tel:+86-13590309162 tel:+86-13590309162  email:info@visztek.com email:info@visztek.com |

Search

|

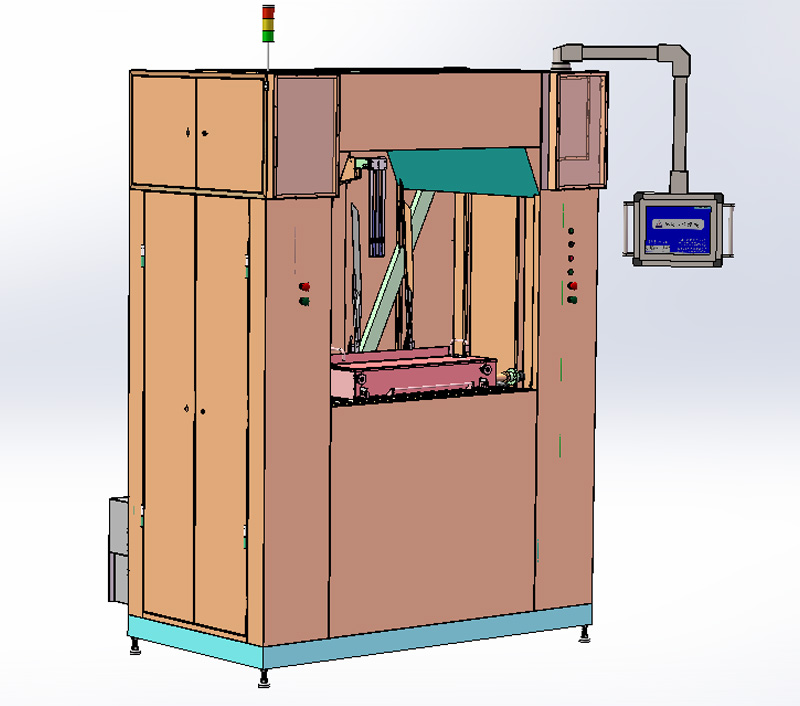

LEAD-FREE HOT AIR LEVELING MACHINE JS-A5001

Product Details

Model: JS-A5001 | |||

Power usage: | 88KW | Stirring temperature: | 250 ~ 280℃ |

Tin furnace capacity: | 1000kg (lead-free tin) | Air knife temperature: | 320℃ ~ 350℃ |

Tin bath temperature: | 250 ~ 280℃ | Air knife pressure: | 3㎏/㎝2 ~ 6㎏/㎝2 |

PCB thickness: | 0.8㎜ ~ 3.0㎜ | Machine weight: | 1470 kg |

PCB maximum operating area: | 700㎜×800㎜ | Mechanical Dimensions: | 2050㎜(L)×1450㎜(W)×2800㎜(H) |

Feature description

Various series of environmentally friendly tin special models ---

1. The heating is rapid, and the preparation is completed in 80~120 minutes.

2. Two-stage exhaust system, safe and sanitary operation.

3. Front lift and full lift two air knife combination, easy maintenance and cleaning inside the tin bath.

4. The air knife is easy to adjust and is most suitable for the high standards of SMT thin lines.

5. Movable guide rail, fast and easy to move.

6. Special drain valve design makes draining easy and safe.

7. Attach the inner baffle of the tin bath to keep the tin dross from overflowing and rebounding.

8. The air pressure is adjusted by a pressure valve, and the air knife pressure is stable.

9. The hot air is the same body as the tin furnace, which reduces space, complements heat and saves energy.

10. The exhaust port is located directly above the tin furnace, and the exhaust is direct for the best effect.

11. The lifting adopts the double-folding type of servo motor belt, the speed is adjustable, and the fastest speed can reach 0.6 seconds/M per meter. It is maintained and adjusted externally, and the maintenance is easy, clean and simple.

12. The tin cylinder and the air knife are made of SUS 316 material, which is corrosion-resistant. The outer body is made of SUS 304, which is strong and durable.

13. The lower exhaust trough adopts the drawer type, the tin oil is separated, and the cleaning is simple and easy.

14. The lower exhaust air has flow control, and the temperature of the tin furnace is well controlled, so that the temperature of the tin furnace mouth will not be too low.

15. The air knife pressure adjustment and the lifting speed adjustment are located on the operating surface, and the adjustment is quick and easy.

16. The upper and lower sections of the tin furnace and stirring are heated, and the temperature is controlled by PLC and SCR. The temperature is stable, which reduces the chance of ignition of the stirring tank. After the shutdown, the residual temperature is less, the solder changes are small, the impurities are reduced, the cost is saved, the quality is improved, and the output is increased.

17. The hot air is controlled by PLC and SCR with good temperature stability.

18. The splint mode, hand-hanging and automatic clamping, can be changed freely.

19. Air pressure parts lubrication valve function, using automatic counting and pushing fuel supply mode, no loss of lubrication.

20. The air-lubricated oil storage barrel is made of SUS 304 material, which is not easy to be damaged. The oil volume does not need to be turned off. The oil level is checked and can be added at any time.

21. The operation of temperature control, air pressure and ascent speed adopts man-machine interface. All are digitalized.

22. The sum of squared production can be calculated to facilitate the management of copper removal.

23. Over-temperature warning and alarm sound function.

24. The air knife pressure test device can be inspected at any time without starting up.

25. Tin furnace mixing temperature, hot air temperature, rise and fall time, air knife pressure, production square meters, can realize data collection, and facilitate tracking management.